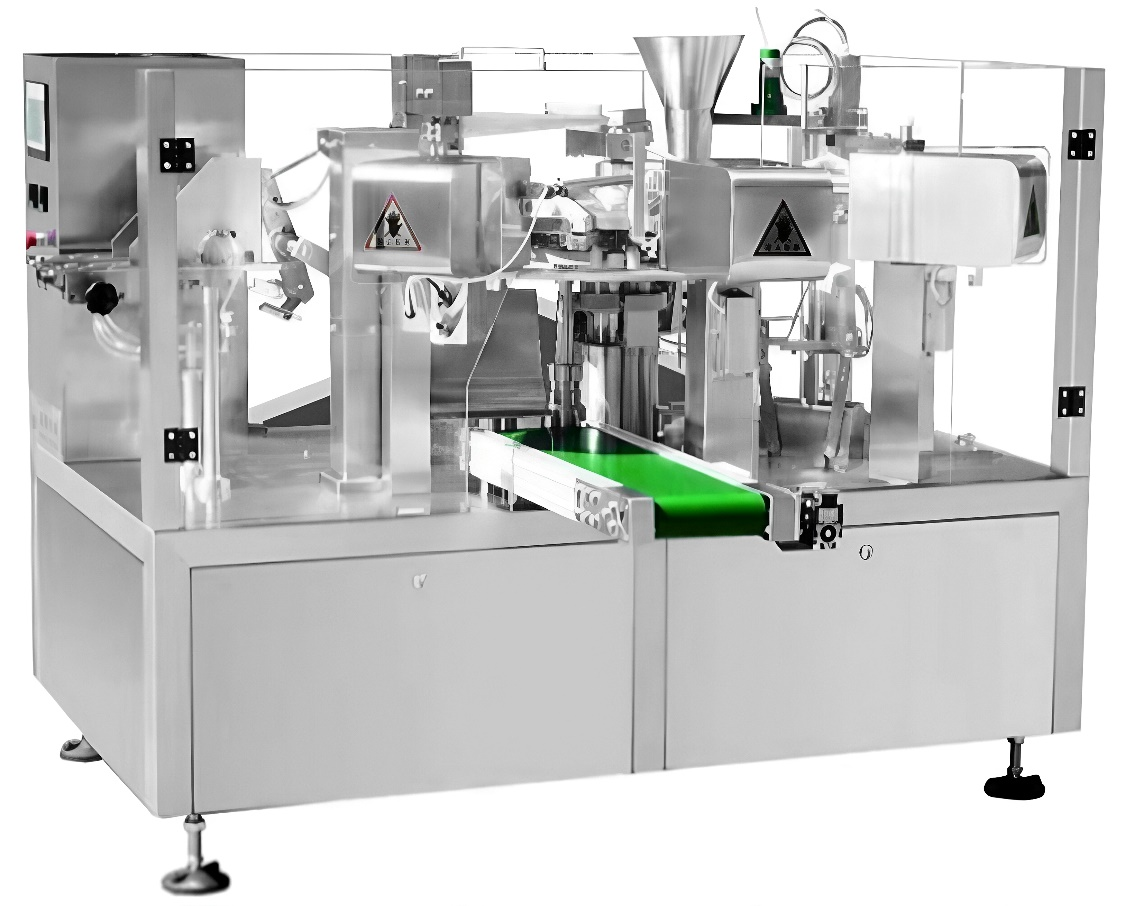

自动包装机(袋)

详细介绍

配置信息:

序号 | 名称 | 型号 | 品牌 | 厂地 |

1 | 显示屏 | SMART 700 IEV3 | 西门子 | 德国 |

2 | PLC | SIMATIC S7-200 SMART | 西门子 | 德国 |

3 | 变频器 | FRN0005C2S-4C | 富士 | 日本 |

4 | 真空泵 | ASV-21 | 艾卡罗 | 浙江 |

5 | 主电机 | YE2-90S-4 | 新菱 | 浙江 |

6 | 分割器 | DS83-6L-120 | 众力 | 浙江 |

7 | 电磁阀 | SY5120 | 亚德客 | 台湾 |

8 | 上袋气缸 | C85N16-20 | SMC | 日本 |

9 | 热封气缸 | ACQ50X30B | 亚德客 | 台湾 |

10 | 下振动气缸 | MG32X75 | 亚德客 | 台湾 |

11 | 吹气阀 | VQ21A1-5G-C8 | SMC | 日本 |

12 | 下开袋气缸 | HFT16X80S | 亚德客 | 台湾 |

13 | 桶料气缸 | MG32X75 | 亚德客 | 台湾 |

14 | 真空阀 | VUVS-L30-M32C | 费斯托 | 德国 |

15 | 真空过滤器 | AF2000-WZ148A | 亚德客 | 台湾 |

16 | 压力表 | DPSN1-10020 | 亚德客 | 台湾 |

17 | 打码机 | HP-501 | 圣龙 | 中国 |

18 | 接近开关 | TL-W5MC1 | 欧姆龙 | 日本 |

19 | 输送带电机 | 5RK90GN-C | 迈力 | 中国 |

20 | 温控仪 | NBG-3400V | 亚泰 | 上海 |

21 | 直线轴承 | / | 易格斯 | 德国 |

22 | 集料斗气缸 | MA25X25SCA | 亚德客 | 台湾 |

23 | 气源两连件组合 | GFR30008AN | 亚德客 | 台湾 |

24 | GFR20008F1 | 亚德客 | 台湾 | |

25 | 接近开关 | PRE-12-4DN | 奥托尼克斯 | 韩国 |

26 | 编码器 | E40S-360-3-N-E | 奥托尼克斯 | 韩国 |

27 | 相序 | KBDS | 欧姆龙 | 日本 |

28 | 交流接触器 | SC-E04P | 富士 | 日本 |

29 | 空开 | BC63E1CG C16 | 富士 | 日本 |

30 | 继电器 | MY2NJ(DC24V) | 欧姆龙 | 日本 |

31 | 电源开关 | MPS-050W24VFS | 米博 | 台湾 |

32 | 拉链袋气缸 | MI12X10CA | 亚德客 | 台湾 |

33 | 拉链袋气缸 | MI25X10CA | 亚德客 | 台湾 |

34 | 拉链袋气缸 | HFT20X40S | 亚德客 | 台湾 |

35 | 电机 | 57BYG250D1 | 亚德客 | 台湾 |

机器视频

技术参数

尺寸图

结构图

留言咨询